MITUTOYO-QUICK VISION Pro Series | JSR GROUP

Evolutionary Advancement

|

Highly Advanced Non-contact Measurement Technologies Well-designed main unit structured for high-accuracy measurement and autofocus. Integration of these high-performance technologies has made 3D non-contact measurement a reality. The QUICK VISION Pro, our CNC vision measuring machine family, never stops evolving |

Enables High-Throughput Measurements Required for Vision Measuring Systems In recent years, the technology surrounding our lives has entered a period of substantial change. Daily updates and technological innovations in motorized vehicles, 5G communications, and IoT technologies are evolving with unprecedented speed. The QUICK VISION Pro was developed to keep pace with these technological innovations and industrial challenges. Experience the high-throughput non-contact measurement that Mitutoyo offers. |

MEDICAL

-Three unique industries benefiting from Mitutoyo’s high reliability. «Medical»

|

Ultra-small Medical devices directly affect people’s health and life. Therefore, every part requires strict adherence to demanding accuracy specifications. The lens and forceps of an endoscope, for example, are installed in a tip with a minimum diameter of 3 mm. With a maximum of 4,300X magnification, various types of autofocus, and high-resolution edge detection, the QUICK VISION Pro allows you to measure objects without making contact for applications that require accuracy at the most minute level. Its improved repeatability and enhanced technical measurement capabilities adhere to the most stringent global standards.

|

Example of measuring a valve used in medical equipment Example of measuring a valve used in medical equipment |

|

Optimized optical system for ultra-small dimensional measurement By combining ten different objective lenses with a built-in imaging lens, a maximum of 150X optical magnification (4,300X total on-monitor magnification) can be achieved. This enables measurement of ultra-small parts, such as medical device components. |

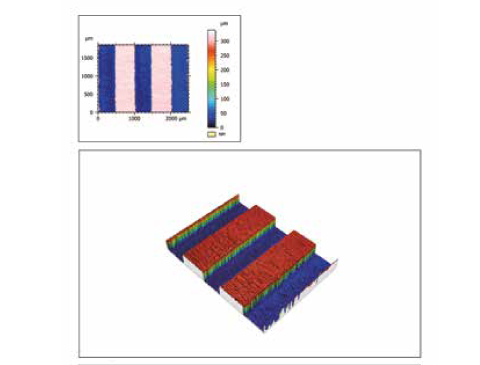

High-accuracy 3D measurement High-accuracy height measurement using single-focus high-resolution images and PFF (Points From Focus) enable 3D capturing of the object shapes, thereby expanding the scope of measurement. |

|

Example of image measurement of medical forceps |

3D analysis of the shape captured by PFF and analyzed with MCubeMap |

AUTOMOTIVE

-Three unique industries benefiting from Mitutoyo’s high reliability. «Automotive»

|

Cutting-edge With the increasing demand for reducing greenhouse gas emissions, automobile production is shifting from petrol and diesel vehicles to electric vehicles, shifting the key automotive parts to now change to electric motors, batteries, and semiconductors at an increasingly rapid rate.

|

|

Meeting the rigorous quality control standards of the automobile industry The introduction of CASE technologies will drive demand for electronic and semiconductor parts in the automotive industry. QUICK VISION Pro offers quality control within the automobile industry by providing both contact and non-contact technologies. Example of measuring an engine control unit |

Enabling online programming using 3D CAD models In addition to online programming using 3D CAD models, an offline program can be created from an image or with a touch probe. This makes it possible to increase the up-time of the QUICK VISION Pro main unit, thereby shortening production lead times. Online programming using 3D CAD models |

SEMICONDUCTOR

-Three unique industries benefiting from Mitutoyo’s high reliability. «Semiconductor»

|

Full automation The shift of production to electric vehicles, expansion of services promoted by commercialized 5G, and recovery of capital investment in data centers are all growing signs of recovery in the semiconductor market. The market is expected to show more growth and will be prepared for mass production to meet increasing demand. QUICK VISION Pro synchronizes main unit operation with the strobe of the camera used for measuring, therefore providing high-speed measurements to enhance the productivity of semiconductor manufacturing. For example, the stage keeps moving without stopping while the system measures many features on the shower head to check for dimensional errors or foreign substances, which can significantly reduce the cycle time. |

|

|

Preventing nonconformities during mass production Continuous measurement by STREAM and quick focusing by TAF can deliver high-speed measurements. This prevents nonconforming final products by increasing the number of features measured.

|

3D measurement with multiple sensors Surface texture and cross-section can be analyzed by combining vision measurement, the non-contact displacement sensor (laser or chromatic position sensor), PFF (Points From Focus), and WLI

|

Flaw Inspection Software DDPAK-QV DDPAK-QV, defect detection software, allows for detection of contaminants, burrs, cracks, etc., in addition to dimensional measurement. Flaws can be found that cannot be detected by typical dimension measurement. Inspection for foreign substances in shower head diameters |